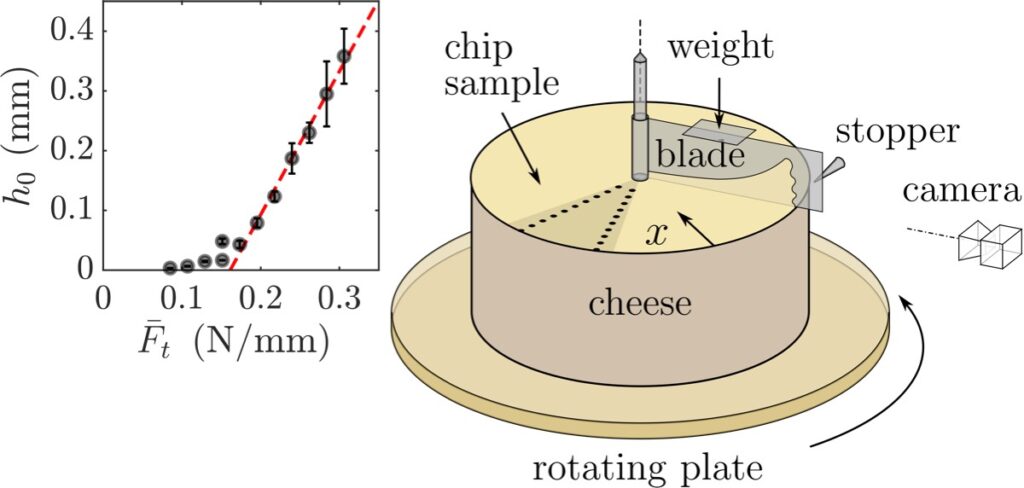

Researchers published a study in Physical Review Letters exploring the mechanics of cheese deformation using samples from the Fromagerie de Bellelay brand. The selected cheese, known as Monk’s head, had been aged between three and six months. Each wheel was halved and mounted on a Girolle device, which was equipped with a motorized base. This setup ensured a consistent rotational speed while keeping the blade in a fixed position.

The experimentation focused on how the cheese transformed during the scraping process. Data collected facilitated the development of a model drawing parallels to metal dynamics across a two-dimensional surface with characteristics akin to cheese.

Findings revealed that friction varied between the core and outer edges of the cheese wheel, with the core retaining moisture more effectively throughout the ripening phase. The harder outer edge exhibited lower friction against the blade, leading to inconsistencies in the thickness of the cheese shavings, resembling delicate rosettes upon scraping.

This modeling approach indicates a novel technique potentially allowing for programmable and intricate shaping derived from simple scraping actions. The authors suggest that their insights could enhance control over the morphogenesis of flower-shaped chips and similar products, extending even to metal cutting applications. Notably, the formation of flower-shaped chips in metal operations has not been previously documented, making the friction dynamics a salient point for material shaping.

For further information, see Physical Review Letters, 2025. DOI: 10.1103/PhysRevLett.134.208201.